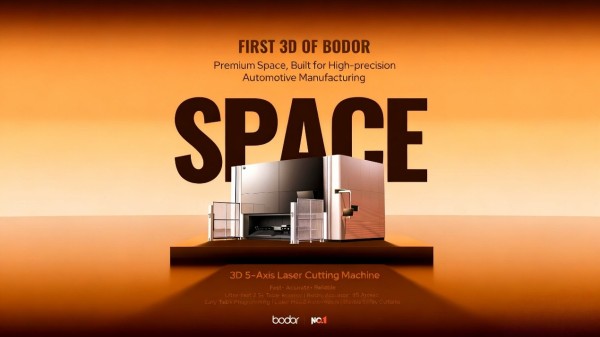

Chicago, United States, 13th Sep 2025 – At the recently concluded FABTECH 2025 in Chicago, Bodor Laser unveiled its latest innovation, the Space Series 3D five-axis laser cutting system, marking the company’s official entry into high-end 3D metal processing. Purpose-built for industries that demand complex, high-precision parts—including automotive, aerospace, mold making, and construction machinery—Space combines speed, accuracy, and reliability to address some of the most challenging fabrication requirements.

Key Advantages of Space Series Include:

- Dual-station rotary table

2.5‑second changeover, ±15‑arcsec accuracy, with synchronized cutting, loading, and unloading to cut idletime and raise throughput. - Round‑the‑clock reliability

Heavy‑duty gantry and wear‑resistant surface handle prolonged high‑load use without loss of accuracy. - Auto-reset cutting head

Restores position within one second after collision, minimizing downtime. - Integrated safety and cleanliness

Light-curtain protection with integrated dust‑removal for a safer, cleaner work zone. - Easy programming and setup

Handheld teach pendant and Tebis offline programming speed toolpath creation and changeovers. - Measurable production gains

Shorter cycles, fewer fixture swaps, reduced rework, and synchronized handling that lowers cost and speeds delivery..

“Our Space Series is a statement of where Bodor is headed in intelligent, high-precision 3D processing,” said Patrick W., Bodor’s Product Director at Global Marketing Center. “It’s designed to deliver higher efficiency, reliability, and competitive advantage to our customers worldwide.”

The new Space Series drew strong interest from FABTECH visitors, with many North American end‑users and distributors scheduling follow‑up demos and test cuts.

Mr. Su, GM of Bodor Laser Inc., reaffirmed the company’s plan to accelerate a Technology & Service Experience Center, expand North American spare-parts warehousing, and grow U.S. local support teams. “Since entering the North American market, we’ve prioritized machine quality, safety, and localization, and we continue delivering both cutting-edge performance and unwavering reliability.” said Su. “This investment will make advanced laser technology faster to access and more reliable to own.”

With six consecutive years as the global sales leader in fiber laser cutters and exports to 180 countries, Bodor is pairing technology depth with stronger local execution—starting with zero-tail tube cutting today, and next-generation 3D processing tomorrow.

Media Contact

Organization: Bodor Laser Inc.

Contact Person: Dennis Wang

Website: https://www.bodor.com/en/

Email: Send Email

City: Chicago

Country:United States

Release id:33867

The post FABTECH Chicago 2025 Bodor Laser Unveils Space Worldwide Its First 3D Five-Axis Laser Leading A New Era of Smart Manufacturing appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Atlas Story journalist was involved in the writing and production of this article.